-

FURNITURE

-

-

-

OUR STORY

Quality Control

Trustworthy Quality Control System

The value we bring to product quality is aligned with industry standards. We guarantee that every product will reflect and help enhance your brand value.

► Experienced Worker

► Experienced Worker

Our artisans have more than 10 years experience in this industry.

► Excellent Qc Team

The average industry experience of QC members is 8 years.

► Authoritative Certificate

FCS, RoHS, REACH and other certifications for different materials.

► Precision Machinery

We introduce advanced machines to improve efficiency and accuracy.

► 100% Full Inspection

100% inspected by professional QC personnel.

Strictly Control The Processing Quality Of Each Process In The Entire Production Process

To ensure the quality of furniture, it is necessary to strengthen the quality control of the production process.

Tri-Tiger quality control team is certified and trained to carry out strict and professional inspection on furniture before, during and after production, ensuring Tri-Tiger furniture meets industry standards and performs at its best.

Before Production Inspection

Production Equipment

The operator performs daily maintenance on the equipment. Before starting production, the operator checks each item according to the equipment inspection sequence, and starts production after confirming that there is no abnormal phenomenon.

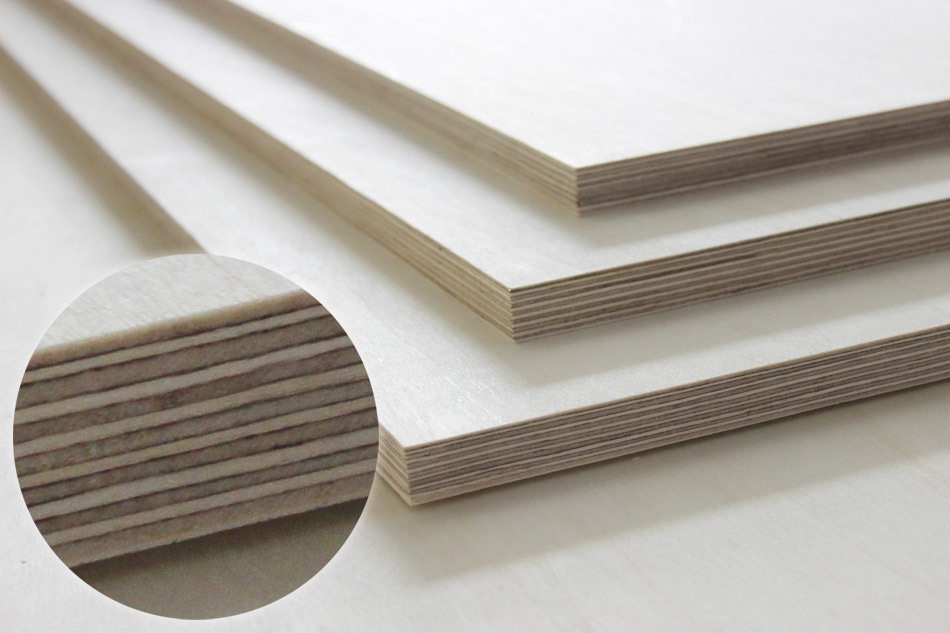

Raw Material

Check the appearance of solid wood and boards, humidity, formaldehyde emission, wood moisture content, etc.

In Production Inspection

Manufacturing Process

Check the effects of sanding, polishing, cutting, painting and more.

Semi-Finished Product Size

Control the error within the normal range.

Before Packing Inspection

Pre-assembled

Pre-assemble the semi-finished products and check the use effect of the finished products.

Hardware Inspection

Check the number of accessories and check the installation effect of hardware accessories.

After Production Inspection

Package Information

Record packaging information, such as package size, product gross weight, logistics information, etc.

Packaging Test

Conduct pressure test, drop test, vibration test and shock test.

Contact Information

E-mail:market@costergroup.cn

Add:Head Office: 2302 Highway Plaza, 101 Garden Road, Jinan, China

Factory1: Maji Town, Dingtao District, Heze, China

Factory2: Niji Town, Cao County, Shandong, China

market@costergroup.cn

market@costergroup.cn

+86-531-8190 7388

+86-531-8190 7388